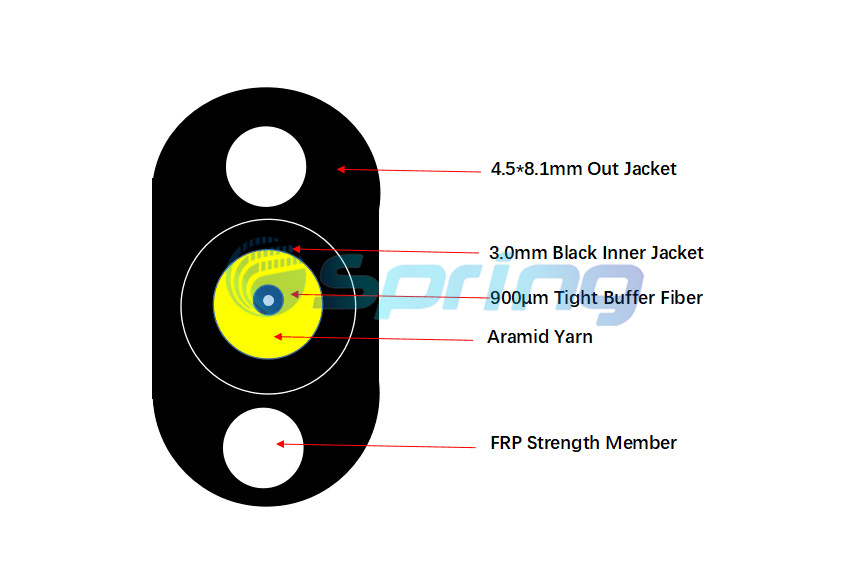

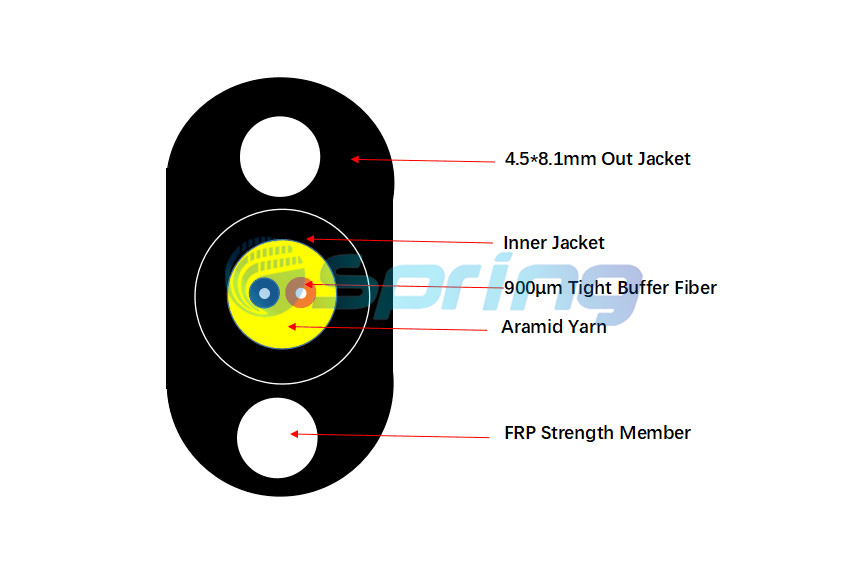

Cable Structure:

| ITEMS |

DESCRIPTION |

| Fiber count |

1-2 |

| Tight buffer |

OD(mm): |

0.9±0.05 |

|

Material: |

LSZH |

| In Sheath |

OD(mm): |

3.0 |

|

Material: |

LSZH |

| Strength member |

Aramid yarn |

| Strength member |

G-FRP-1.6mm |

| Sheath |

Thickness: |

Non. 0.8mm |

|

Material: |

HDPE |

| OD of cable (mm) |

4.5*8.1mm±0.3 |

| Net weight ( kg/km) |

40 |

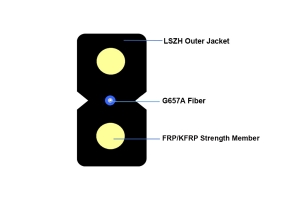

Optical Fiber:

| ITEMS |

UNITS |

SPECIFICATION |

| Fiber type |

|

G652D |

G657A |

| Attenuation |

dB/km |

1310nm ≤ 0.36

1550nm ≤ 0.22 |

| Chromatic Dispersion |

ps/nm.km |

1310nm≤ 3.5

1550nm≤ 18

1625nm≤ 22 |

| Zero Dispersion Slope |

ps/nm2.km |

≤ 0.092 |

| Zero Dispersion Wavelength |

nm |

1300 ~ 1324 |

| Cut-off Wavelength (lcc) |

nm |

≤ 1260 |

| Attenuation vs. Bending

(60mm x100turns) |

dB |

(30mm radius,100ring

)≤ 0.1 @ 1625nm |

(10mm radius,1ring)≤ 1.5 @ 1625nm |

| Mode Field Diameter |

mm |

9.2 ± 0.4 at 1310nm |

9.2 ± 0.4 at 1310nm |

| Core-Clad Concentricity |

mm |

≤ 0.5 |

≤ 0.5 |

| Cladding Diameter |

mm |

125±1 |

125±1 |

| Cladding Non-circularity |

% |

≤ 0.8 |

≤ 0.8 |

| Coating Diameter |

mm |

245±5 |

245±5 |

| Proof Test |

Gpa |

≥ 0.69 |

≥ 0.69 |

Mechanical And Environmental Performance Of The Cable

| NO. |

ITEMS |

TEST METHOD |

ACCEPTANCE CRITERIA |

| 1 |

Tensile Loading Test |

#Test method:IEC 60794-1-E1

-. Long-tensile load:350N

-. Short-tensile load:800N

-. Cable length:≥50m |

-. Attenuation increment@1550nm:≤0.1dB

-. No jacket cracking and fiber breakage |

| 2 |

Crush Resistance Test |

#Test method:IEC 60794-1-E3

-.Long load:300 N/100mm

-.Short load:1000 N/100mm

Load time:1 minutes |

-. Attenuation increment@1550nm:≤0.1dB

-. No jacket cracking and fiber breakage |

| 3 |

Impact Resistance Test |

#Test method:IEC 60794-1-E4

-.Impact height:1m

-.Impact weigh: 450g

-.Impact point:≥5

-.Impact frequency:≥3/point |

-. Attenuation increment@1550nm:≤0.1dB

-. No jacket cracking and fiber breakage |

| 4 |

Repeated Bending |

#Test method:IEC 60794-1-E6

-.Mandrel diameter:20D (D = cable diameter)

-.Subject weight:15kg

-.Bending frequency:30 times

-.Bending speed:2s/time |

-. Attenuation increment@1550nm:≤0.1dB

-. No jacket cracking and fiber breakage |

| 5 |

Torsion Test |

#Test method:IEC 60794-1-E7

-.Length:1m

-.Subject weight:25kg

-.Angle:±180 degree

-.Frequency:≥10/point |

-. Attenuation increment@1550nm:≤0.1dB

-. No jacket cracking and fiber breakage |

| 6 |

Water Penetration Test |

#Test method:IEC 60794-1-F5B

-.Height of pressure head:1m

-.Length of specimen:3m

-.Test time: 24 hours |

-. No leakage through the open cable end |

| 7 |

Temperature Cycling Test |

#Test method:IEC 60794-1-F1

-.Temperature steps:+20℃,-40℃,+70℃,+20℃

-.Testing Time:24 hours/step

-.Cycle index:2 |

-. Attenuation increment@1550nm:≤0.1dB

-. No jacket cracking and fiber breakage |

| 8 |

Drop Performance |

#Test method:IEC 60794-1-E14

-.Testing length:30cm

-.Temperature range:70±2℃

-.Testing Time:24 hours |

-. No filling compound drop out |

| 9 |

Temperature |

Operating:-40℃~+60℃

Store/Transport :-50℃~+70℃

Installation -20℃~+60℃ |